Products

AVATEC Creates New Technology for MLCC

Etching/ITO Coating Business

Overview

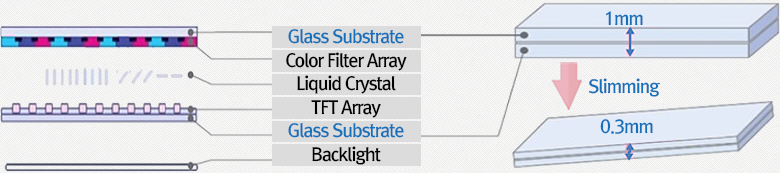

According to the lightweight and thin display trend, the slimming technology is applied to overall mobile displays such as smartphone, ultra-book, tablet PC, etc. applied with thin and high quality panel by applying the chemical etching technology to the display panels such as LCD and OLED and the range of device is being expanded gradually.

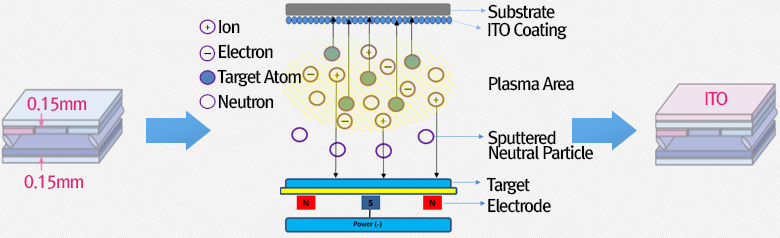

AVATEC possesses the best slimming/ ITO coating technology and promise you to provide the high quality and mass-production service by incorporating the ITO coating to remove the static electricity from the panel after slimming process into the process line.

Applied Technology

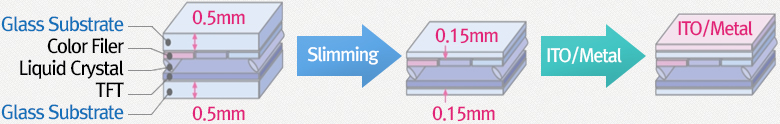

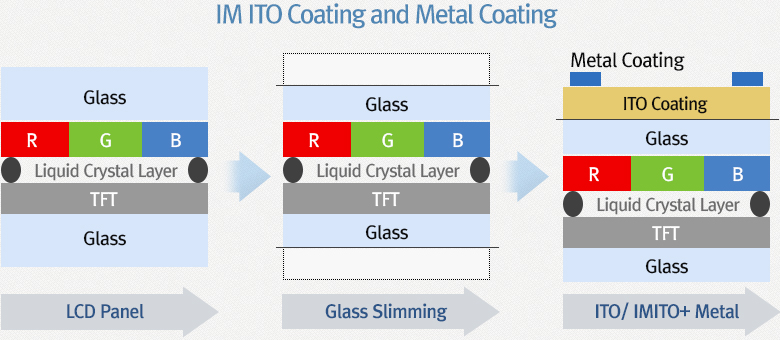

- Slimming process technology: As a essential technology to implement the lightweight and thin LCD panel, it makes the LCD panel (C/F filter + TFT Glass) from the thickness of 1.0mm to the thickness 0.3mm or less

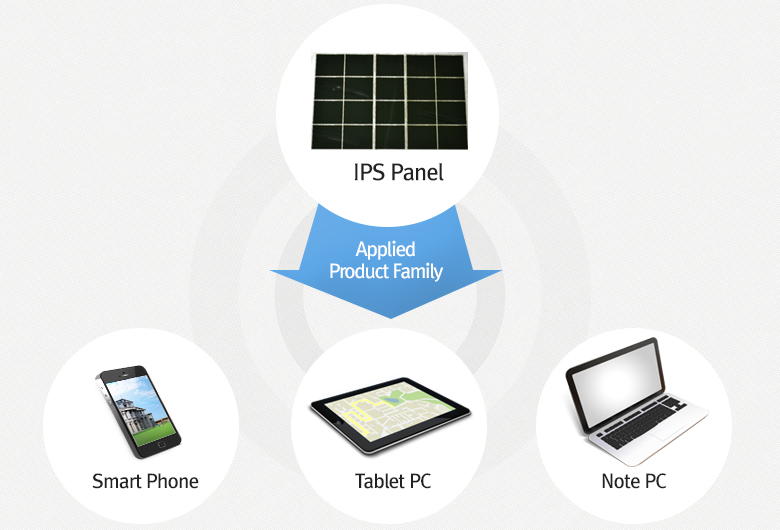

- IMITO & Metal Coating: Is the essential technology for IPS panel to form the pattern to improve the IPS panel touch

We are applying the advanced process technology to the panel to maintain the film uniformity, light penetrability and color reproducibility of the panel after etching through large area etching equipment

Slim Etching Patent

Starting from 2010, we registered the patents for glass substrate etching equipment and secured the proprietary technologies through constant patent registration since 2010

| Application No. | Registration No. | Patent Right | Reason for Major Patent Selection |

|---|---|---|---|

| 10-2010-0094056 | 1010267440000 | Registered | Glass substrate for LCD etching equipment and manufacturing method and technology |

| 10-2011-0051873 | 1010681130000 | Registered | Glass substrate for LCD etching equipment and manufacturing method and technology |

| 10-2011-0051876 | 1010681140000 | Registered | Glass substrate for LCD etching equipment and manufacturing method and technology |

| 10-2012-0014587 | 1013910780000 | Registered | Glass substrate for LCD etching equipment and manufacturing method and technology |

Etching Panel Specification

| Product Specification | X-bar Control Line Control Specification | R-Control Line Control Specification |

|---|---|---|

| 5G Glass or under | 10 ± 18㎛ | 20㎛ (0.00%) |

| 5G Glass or under | 10 ± 20㎛ | 30㎛ (0.00%) |

Since the display may malfunction by the static on the slimmed panel, the static elimination technology is applied through the vacuum deposition of transparent conductive film (ITO) on the panel.

ITO Panel Specification

| Product Specification | Sheet Resistance Control Specification | Transmissivity (550nm) |

|---|---|---|

| 250Ω/□ | 250 ± 30Ω/□ | 92.0% or more |

| 500Ω/□ | 500 ± 50Ω/□ | 96.5% or more |

| 5Ω/□ | 5K ± 1KΩ/□ | 99.0% or more |

IM ITO/ Metal Coating for Touch

To improve the force touch, we apply the pattern metal electrode technology and implement the micro-pattern with sputtering engineering using shadow mask.

Applications

Specifications

| Description | Specification | |

|---|---|---|

| Glass Slimmin | Size | 1100x1250 |

| Slimming Thickness | ~ 0.3mm | |

| Sputter Coating (ITO/ IMITO) | Sheet Resistance | ~200Ω/□ |

| Transmissivity | 96~99% | |

| Metal Pattern Electrode | Pattern | ~1.0㎜ |

| Sheet Resistance | 10±2Ω/□ | |

Etching /Back ITO In-line Process

Built the integrated production system of Bonding → Cleaning → Etching → ITO Line (Save the unnecessary material transfer cost and improve the production quality by integrating etching and back ITO processes)