SMVR Products

Compact SMVR that opens the future with new challenges

SMVR ProductsQuality Competitiveness of SMVR

SMVR ProductsQuality Competitiveness of SMVR

Quality Competitiveness of SMVR

Comparison analysis of product competitiveness for technology/quality/price

with products of domestic and overseas competitors

| Item | SMVR–desalination system | RO-desalination system | Other manufacturers MVR–desalination system |

Remarks |

|---|---|---|---|---|

| MVR–desalination system | ||||

| Environmental pollution by drainage | No impact at all (eco-friendly) | Give impact | No impact at all (eco-friendly) | |

| Chemical input | Not necessary | Absolutely necessary | Not necessary | |

| Sterilization | Not necessary | Absolutely necessary | Not necessary | |

| Pre-treatment facility | Not necessary | Absolutely necessary | Not necessary | |

| Post-treatment facility | Not necessary | Absolutely necessary | Not necessary | |

| Water quality | Very good water | Good water | Very good water | Korean standard |

| (TDS < 100ppm) | (100 < TDS < 500ppm) | (TDS < 100ppm) | TDS < 500PPM | |

| Major services | Low pressure commercial pump seal | High pressure pump parts and seal | Commercial pump parts and seal | |

| Filter, etc. | ||||

| System elements and maintenance | Very simple and easy | Very complicated and difficult | Complicated and difficult | |

| (Need no expert) | (Need an expert) | (Need an expert) | ||

| Desalination ability | Remove salt by 100% | Cannot remove salt by 100% | Remove salt by 100% | |

| Purification efficiency | High ( constant ) | Low ( Inconstant ) | High ( Constant but lower efficiency in scale than Doowon’s system ) | |

| No cyclic parts replacement (Semi-permanent) | No ( Semi-permanent ) | Must replace the parts cyclically | No | Except motors and pumps available in the market |

| Water production cost (USD) /Ton | $ 4.2 ( Low ) | $ 7.3 ( High ) | $ 5.7 ( Moderate ) | Korean standard |

| Initial investment (System price) | High ( @ 1 billion Won ) | Low ( @ 700 million Won ) | Higher than Doowon’s system (@1.8 ~ 2 billion Won) | (Based on 100 tons) |

| Purification treatment of contaminated seawater/flood tide | Purification treatment is possible | Not possible | Purification treatment is possible | |

| Technical level and quality | Very hight (High dimensional vaporizing technology) | Low ( Reverse osmosis filtering ) | High ( High dimensional vaporizing technology ) | |

| Applicable to ships and marine plant | Most suitable (Minimize the installation area) | Suitable ( Under use ) | Impossible ( Excessive installation area ) |

Comparison analysis of vaporizing system

| Item | MVR (Mechanical Vaporizingand high concentrated Re-Compression System) |

TVR (Thermal Compression System) |

MED (Multi Efficiency Vaporizing System) |

MSF (Multi Step Vaporizing System) |

Remarks |

|---|---|---|---|---|---|

| ▶ Relative efficiency | 25 | 5 | 2 | 1 | Heat recovery stage |

| ▶ Relative size | Very Low | Low | Medium | Large | based on the same capacity |

| ▶ Energy required | Electricity | Fuel + Electricity + Steam | Fuel or Electricity + Steam | Electricity + Steam | TVR, MED, MSF desalination system requires lots of energy |

| ▶ Production space | Low | Medium | Large | Large | - |

| ▶ Technical level | Very High | High | Medium | Low | MVR is produced by technically developed countries |

| ▶ Related companies | Doowon TEG (Korea) Sasakura (Japan) IDE (Israel) |

Sasakura (Japan) Korean Companies |

Doosan Hyundai | Doosan Hyundai | - |

| ▶ Essential requirements | Electric heater + urbo steam compression system |

Fuel used heating system + High pressurized steam system |

Fuel or electricity used steam system (TVC) + High capacity electric system |

Steam turbine or heat recovery boiler system + High capacity electric system |

TVR, MED or MSF equipment has very complicated structure purification method that it is not possible to operate without expert |

Comparison of Purification Treatment Systems

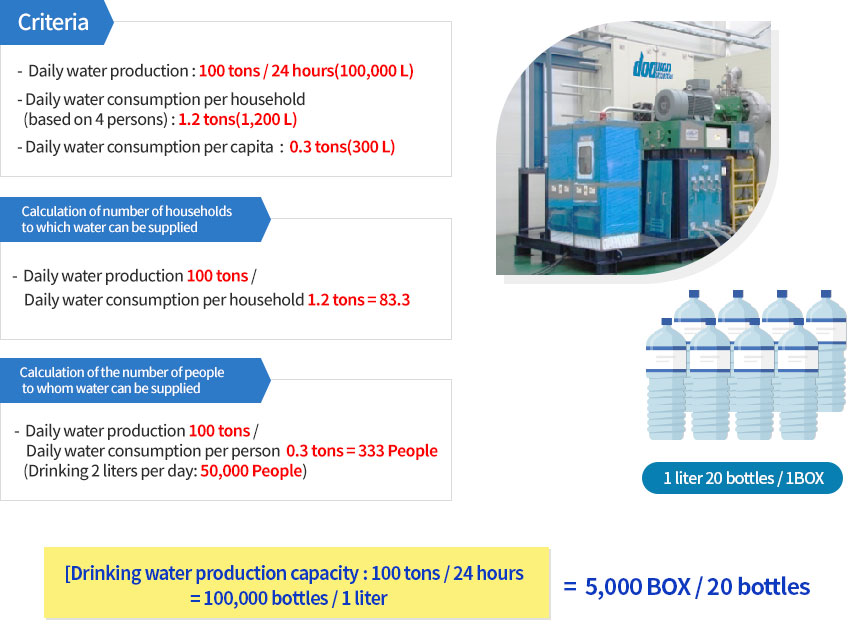

Water treatment cost analysis of SMVR-desalination system

- Electric energy required for producing one ton of water : 50 kwh/ton

- Water production cost : 50 kwh/ton x 100 Won/kwh = 5,000 Won/ton 1 kwh = 100 Won. Korea) (5.0 Won/liter)

Electrical specification of SMVR Facility

| Model | Distillation per hour (Ton/h) |

Evaporative concentration performance (KWh/Ton) |

Electric capacity (KW) |

Electric power consumption(KWh) | Moter | ||||

|---|---|---|---|---|---|---|---|---|---|

| Normal operation (average) | Performance guarantee under contract | Normal operation (average) basis | Basis for performance guarantee under contract | Preparation capacity (1 unit) of electric facility | Average daily power consumption (kwh) |

Type | capacity (KW) | ||

| SMVR 10 | 0.417 | 75 | 90 | 31 | 38 | 64 | 751 | Screw | 37 |

| SMVR 25 | 1.042 | 50 | 60 | 52 | 63 | 106 | 1,250 | Turbo | 55 |

| SMVR 50 | 2.083 | 50 | 60 | 104 | 125 | 212 | 2,500 | Turbo | 110 |

| SMVR 75 | 3.125 | 50 | 60 | 156 | 188 | 319 | 3,750 | Turbo | 160 |

| SMVR 100 | 4.167 | 50 | 60 | 208 | 250 | 425 | 5,000 | Turbo | 200 |

| SMVR 200 | 8.333 | 50 | 60 | 417 | 500 | 850 | 10,000 | Turbo | 350 |

1) Installation capacity of electric facility (1 unit) = Guaranteed performance under contract (KWh/Ton) X Distillation per hour(Ton/h) X 1.7(Power peak ratio)

2) Installation capacity of electric facility (N units) = Installation capacity of electric facility (1 unit) + (N-1) *Electric capacity of guaranteed performance under contract

Ex) In case of 5 units of SMVR100 :

Installation capacity of electric facility (1 unit) = 60*(100/24)*1.7=425(kW)

Installation capacity of electric facility (5 units) = 425+(5-1)*250=1,425(kW)

Average daily power consumption = 50(kWh/ton)*100(ton/day)=5,000(kWh/day)